Fabrication

Our shop is divided into five divisions: Cutting, machinery, welding, assembly and sheet metal shop. While each of these shops are managed separately to maintain their focus, they work in synergy to deliver a final product which is exact in details and robust as a whole.

we are equipped with guillotine, laser, waterjet, plasma and oxy-fuel cutting machines in our cutting division.

In machinery division our technicians while equipped with CNC machines, lathes and radial drills are extremely skillful as many acquired their expertise in demanding aerospace industries.

Pidemco’s bold history in welding various alloys and our full range of welding processes such as ESW, SAW, SMAW, TIP-TIG, and GTAW makes us consider ourselves one of the most expert

companies in the region.

Our sheet metal shop is highly active in railroad and automotive industries. Beside our laser cutting machines, our bending and punch equipment provide valuable services to our clients as well. Assembly Team of Pidemco by combining the know-how of the experienced and creativity of the young works to find innovative ways for assembly and fabrication of intricate configurations.

Read More +

Weld overlay cladding - S.S.347 over CroMoly Gr.22 by Electroslag machine

Welding Triple joint to Head by SAW under 250 deg. C preheat

Weld Overlay Cladding of Ellip. Head by TIP-TIG

Tubesheet Drilling

TIG Root Pass Welding of Nozzle to Head

Manufacturing Transfer line exchanger

Machining body flange by Lathe

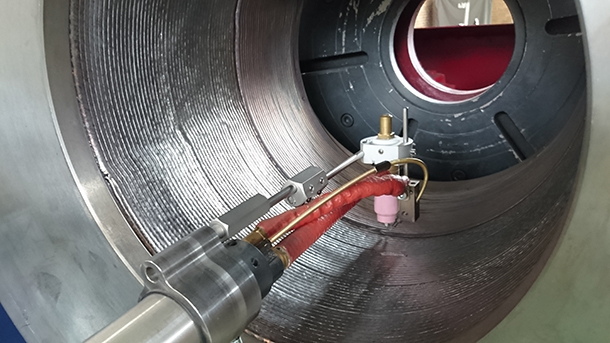

Cladding inner diameter of Nozzle by TIP-TIG

Capabilities

-

cutting

Most of the time our manufacturing activities start in cutting the materials. This process is vital in two aspects; first, it is the basis for our dimensional accuracy in later steps; and the second, it has direct effect on welding as it prepares weld edges. Accurate weld configurations avoids excess/ lack of weld gaps which in turn affects weld quality. Our expert personnel and wide range of cutting technologies help us to achieve both these necessities.

Our high-tech laser, water-Jet and plasma CNC cutting produces very thin HAZ area and results in added quality of the final equipment.

Laser cutting machines Thickness range up to 21mm almost all Materials

Water-Jet cutting machine thickness range up to all materials

Plasma Cutting machines thickness range up to

Oxy-fuel cutting machines thickness range up to carbon and low alloy steels

-

Fit up

Pidemco’s fabricators team has been developed and uses creative jigs and fixtures to avoid excess use of tag welds in assembly of the parts. They have done unrivalled works to date; and they make us astonished by their genuine solutions in different projects to achieve strict exactness.

-

Machining

Tight tolerances would eliminate many inconveniences during operation and maintenance. We make our tubesheets, girth flanges and other intricate assemblies by combining various machining methods to attain the strict dimensional accuracy. Many of our technicians and engineers in this unit acquired their experience in demanding aero-industries and are highly adept in their work.

-

Sheet Metal

Our technicians are obsessed with precision in our sheet metal division. By employing advanced cutting, bending and punching machines we fabricate equipment parts such as internals, baffles and etc. with such quality which is noncompetitive in the industry.

-

Forming & Rolling

We are able to form up to 100 mm in thickness and 6 m in diameter in Pidemco. Our history in manufacturing huge equipment _ in thickness and diameter _ is a solid ground for our success in future projects.

-

Welding

The most critical step in our line of work is welding. Low heat input, accurate and defect-free welds are the ground work for a quality finished product. Pidemco’s skilled welders equipped with latest welding technology make this happen. Our cutting-edge electro-slag welding, sub merged welding, Tip-Tig welding machines makes it easy to adapt the best method to produce the most quality welds. We are also very experienced in working with variety of materials ranging from plain carbon steels, which are common, to CroMoly or titanium alloys, which call for deep know-how.

-

Cladding Solutions

Pidemco’s cladding solutions while saving our clients resources, provide strength and durability. We are equipped to perform overlay cladding by SAW, ESW and TIP-TIG inside heads, shell courses, flanges and nozzles up to 12mm. We have extensive experience in cladding S.S.316,S.S.347,MONEL, COPPER-NICKLE, and BRASS on, carbon steels, Low alloy steels(Cromoly gr.11,22,…) and variety of other materials.

-

Standards

TEMA Manufacturing of Heat Exchangers

-

Personnel

|

Unit

|

No. of perssonel

|

|

Production Engineering

|

25

|

|

Production control Unit

|

30

|

|

Fit up shop

|

15

|

|

Welding shop

|

35

|

|

Cutting shop

|

10

|

|

Forming shop

|

5

|

|

Machining shop

|

15

|

|

workers

|

20

|

Link to Facilities page